The PDIC TR 100 is a portable, single-phase transformer turns ratio (TTR) tester manufactured by the Power Diagnostic Instrument Company (PDIC). This microprocessor-based instrument is engineered for field and laboratory use to accurately measure the turns ratio of single-phase and three-phase transformers, as well as potential and current transformers.

The primary function of the TR 100 is to determine the ratio of the number of turns in the primary winding to that in the secondary winding of a transformer. This measurement is crucial for verifying the transformer’s nameplate specifications, diagnosing winding faults, and ensuring proper operation.

The PDIC TR 100 operates by applying a known AC voltage to the high-voltage winding of the transformer under test and precisely measuring the induced voltage on the low-voltage winding. The ratio of these two voltages directly corresponds to the transformer’s turns ratio. The instrument performs this measurement in accordance with the IEEE C57.12.90 standard.

Turns Ratio Measurement: It can measure turns ratios from 0.8 to 30,000 with a high degree of accuracy.

Excitation Current Measurement: The device measures the excitation current, which is the current required to magnetize the transformer core. Abnormal excitation current can indicate a shorted turn or other core issues.

Phase Angle Measurement: The TR 100 measures the phase difference between the primary and secondary winding voltages, which is important for identifying winding polarity and vector group configurations in three-phase transformers.

Polarity Indication: It automatically determines and displays the winding polarity.

Selectable Test Voltages: The unit offers multiple test voltages, typically 4 Vac, 40 Vac, and 100 Vac, to accommodate a wide range of transformer sizes and types. Higher test voltages can improve accuracy, especially in noisy environments.

Data Storage and Reporting: Test results can be stored internally and transferred to a computer for analysis and report generation using accompanying software. This facilitates record-keeping and trend analysis of transformer health.

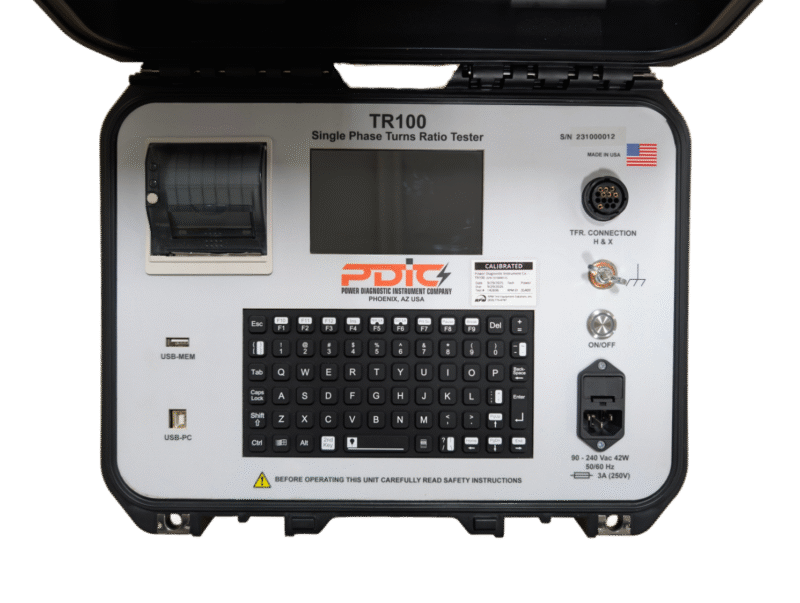

Portability and Durability: Housed in a rugged case, the TR 100 is designed for field use. It is lightweight and often features a rechargeable battery for operation in locations without a direct power source.

User Interface: A clear LCD screen and a user-friendly interface allow for easy operation and viewing of test results, even in bright sunlight.

Physical Specifications | ||

|---|---|---|

Dimensions | 14.75″L x 12” W x 7.25″H (37.5 cm x 30.5 cm 18.5 cm) | |

Weight | Weight without Battery: 12 lbs. (5.5 Kg) | |

Weight with Battery | Weight with Battery: 14 lbs. (6.4 Kg) | |

Operating Voltage | 90 ¬ 240 Vac, 50/60 Hz | |

Measuring Method | ANSI/IEEE C57.12.90 | |

Turns Ratio Accuracy | ||

1 Vac: 0.75¬ 14,999 : ±0.2% | ||

4 Vac: 0.75 ¬ 14,999 : ±0.1% | ||

40 Vac: 0.75 ¬ 14,999 : ±0.1%, 15,000-30,000: ±0.2% | ||

100 Vac: 0.75¬ 14,999 : ±0.1%, 15,000 ¬ 30,000: ±0.2% | ||

250 Vac: 0.75¬ 14,999 : ±0.1%, 15,000 ¬ 30,000: ±0.15% | ||

Phase Angle Measurement | ||

Accuracy | ±0.5 degree (±1 digit) | |

Polarity Reading | In-phase or out-of-phase indication | |

Display | Touch enabled 800 x 480 pixels back-lit color LCD; viewable in direct sunlight | |

Keyboard | Full-sized “QWERTY”-style industrial keyboard | |

OPERATING/STORAGE TEMPERATURES | ||

Temperature | Operating: -10°C to +50°C (+15°F to +122°F) Storage: -30°C to +70°C (-22°F to +158°F) | |

Humidity | 90% RH @ +40°C (+104°F) | |

DATA STORAGE AND ANALYSIS | ||

Internal Test Record Storage | Up to 128 records with max 33 results per record | |

External Test Record Storage | USB Flash drive interface and firmware updates | |

Warranty | 2 years on parts and labor | |

Test Cables | 15′ (4.6m) single phase cable, power cord, USB cable, 10’ ground cable and cable bag. Extension test cable of 25′ ft available as option. | |

Transformer Manufacturers: For quality control and verification of design specifications.

Electrical Utilities: For routine maintenance, commissioning of new transformers, and troubleshooting of in-service units.

Industrial Maintenance Crews: For predictive and preventive maintenance of critical power system components.

Testing and Service Companies: For providing comprehensive transformer testing and diagnostic services.